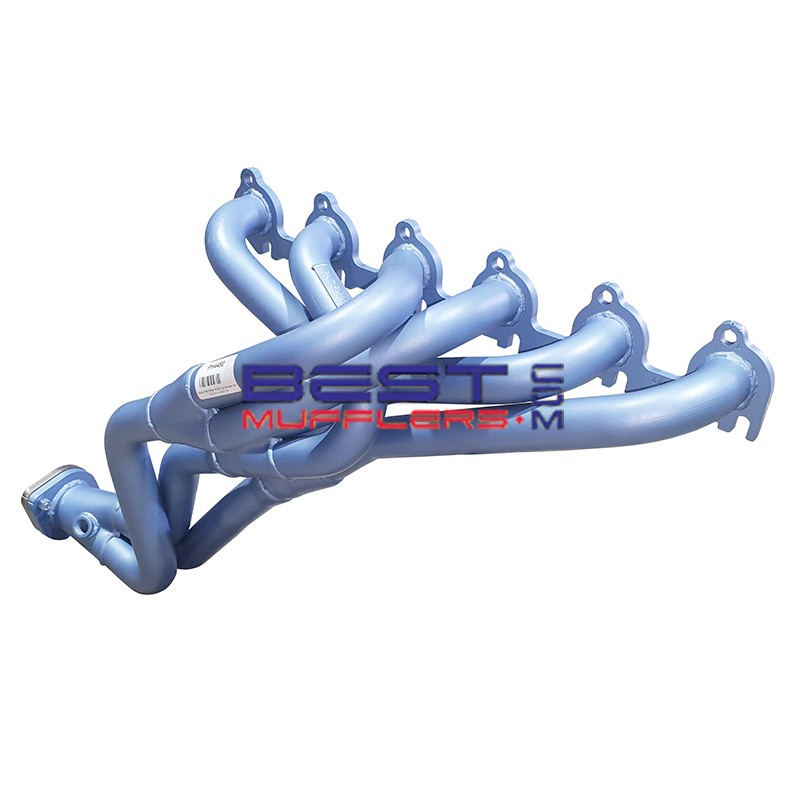

Ford Falcon

EA EB ED EF EL AU inc XR6

3.9 & 4.0 Manual & Automatic

Pacemaker Headers / Extractors

PN# PH4480

| Ford Falcon EA EB ED EF EL AU inc XR6 3.9 & 4.0 Manual & Automatic Pacemaker Headers / Extractors |

|||||||||

| Part No. | PH4480 | ||||||||

| Header Design | Competition Headers Interference design for street performance applications. |

||||||||

| Pipe Sizes |

|

||||||||

| Notes | Gasket see "DSF061" Ceramic Coating available see "PHC65" Will not fit XG Ute Will not fit LPG [See PH4499] Direct fit high flow cat available |

||||||||

|

Installation Tips A great way to fit Pacemaker Headers without scratching the headers or the engine bay during installation is to wrap headers in cling wrap. The more layers added the better chance of preventing any damage. Once wrapped nice and tight, trim around header mounting flange with razor blade or scissors then place headers into engine bay, install a few bolts, then cut the remaining cling wrap away with scissors or razor before tightening. |

|||||||||

|

|

If you need help finding the correct exhaust system parts please Contact Us

WHAT IS THE DIFFERENCE BETWEEN HEADERS AND EXTRACTORS? In Australia, headers were known as extractors through the 60's and 70's by the companies developing them. In America at the same time they were called headers (spelt hedders). This was in part due to the fact that they (headers) are an extension of the cylinder head. In the 80's new Australian companies began to market extractors as headers. The main reason being that these companies intended to change the image of the humble extractor to more of a common vehicle replacement component. Some 'old school' enthusiasts still call them extractors today.

You might also like